We recommend a three phase electric motor for its’ simple, reliable, and energy efficient operation. If you do not have three phase power available, a single phase motor option is also available. You can also choose an air motor drive for the unit if you are in an all air shop or have a space constraint, etc.

This page will show some basic motor configurations. It will use the electric motor as an example, but the pneumatic motor drive options are similar. Motors for the 5000 Series AutoDrill are generally available from 1/3 HP to 3 HP. Almost all motor drive arrangements can also make use of a gear reducer for lower RPM applications.

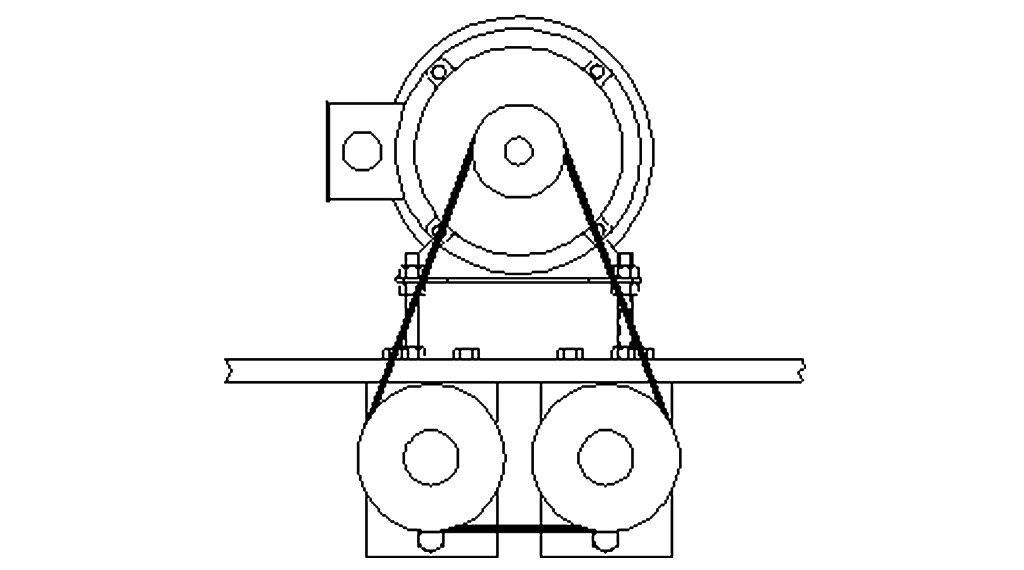

Almost all 5000 Series self feeder AutoDrill units are driven by high quality, anti-slip HTD timing belt and pulley set-ups. These are toothed sets for positive drive action.

Typical Motor & Automatic Drill Drive Arrangements:

Direct Drive Configuration. The Output Speed of the Motor is the Same as the Tool RPM with this Configuration.

Custom Multiple Drive Arrangement.If you have a Special Need, Please Contact us. We can Often Meet That Need. Some Other Offerings Include Off-Set Drives, Close C-C Drives, Right Angle Drives, etc.

Electric Motor Advantages:

Air Motor Advantages: