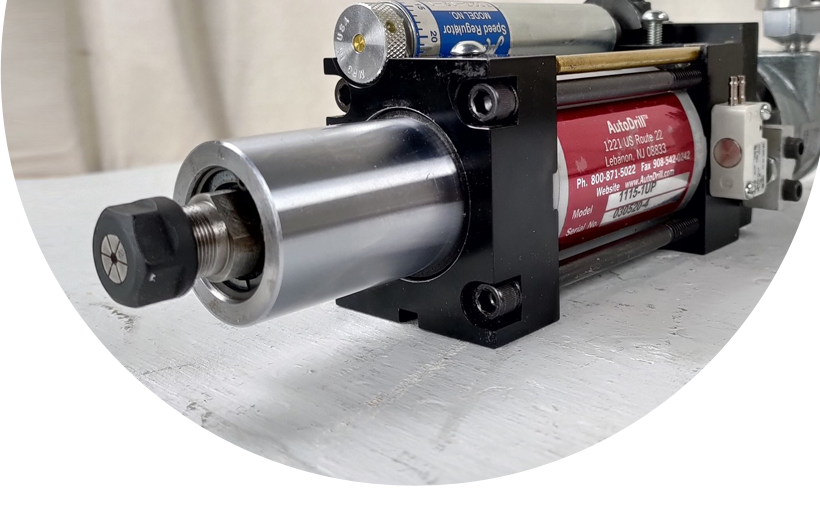

En AutoDrill, reconocemos el papel crítico que los taladros industriales juegan en el sector de la mecanización de precisión. Estas herramientas poderosas son indispensables para crear agujeros precisos en una variedad de materiales, convirtiéndose en piedra angular de nuestra operación y de la industria manufacturera en general. Ya sea trabajando en componentes automotrices, piezas aeroespaciales o proyectos de fabricación personalizados, la versatilidad y confiabilidad de un taladro industrial no pueden ser subestimadas.

Nuestro viaje al mundo de la perforación de alta precisión nos ha enseñado que no todos los taladros son iguales. La elección entre un taladro estándar y un taladro de grado industrial puede afectar drásticamente el resultado de un proyecto. La capacidad de un taladro industrial para manejar materiales de alta resistencia, mantener la precisión bajo estrés y operar de manera consistente durante largos períodos lo convierte en un activo invaluable en nuestro arsenal.

Elección del Taladro Correcto

El Equilibrio entre Potencia y Precisión

Al seleccionar un taladro industrial, el equilibrio entre potencia y precisión es fundamental. Nuestros proyectos a menudo requieren perforar a través de materiales difíciles, donde la potencia de un taladro determina su eficiencia y efectividad. Sin embargo, la potencia sin control puede conducir a inexactitudes, lo cual es inaceptable en nuestra línea de trabajo. Por lo tanto, evaluamos meticulosamente los taladros para asegurarnos de que proporcionen el equilibrio perfecto para las necesidades de nuestros clientes.

Versatilidad en las Aplicaciones

Otro aspecto vital que consideramos es la versatilidad de un taladro. La capacidad de un taladro industrial para adaptarse a diferentes materiales y requisitos de perforación sin comprometer la calidad es crucial. Esta adaptabilidad no solo mejora nuestra oferta de servicios, sino que también garantiza que podamos manejar proyectos diversos con una sola solución robusta.

Innovaciones en la Perforación

El panorama de la perforación industrial está en constante evolución, con avances tecnológicos desempeñando un papel significativo. En AutoDrill, nos mantenemos al tanto de estos desarrollos, incorporando las últimas innovaciones en nuestros servicios. Por ejemplo, los avances en materiales de brocas han permitido realizar operaciones de perforación más precisas con menos desgaste en el equipo.

De manera similar, la integración de la tecnología de control numérico computarizado (CNC) ha revolucionado nuestra forma de abordar los proyectos de perforación. La perforación CNC permite una precisión, repetibilidad y eficiencia sin precedentes, haciendo que las tareas de perforación complejas sean más manejables y menos consumidoras de tiempo.

Nuestro Compromiso con la Calidad

La calidad es la piedra angular de todo lo que hacemos en AutoDrill. Nuestro compromiso se extiende más allá de simplemente seleccionar el taladro industrial adecuado; abarca todos los aspectos de nuestra operación. Invertimos en máquinas de alta calidad, mantenemos estándares rigurosos para nuestras brocas y accesorios, y capacitamos regularmente a nuestro equipo para asegurarnos de que sean expertos en las últimas técnicas y tecnologías de perforación.

Este compromiso inquebrantable con la calidad no solo mejora nuestra reputación, sino que, lo que es más importante, garantiza que siempre superemos las expectativas de nuestros clientes. Al esforzarnos siempre por ofrecer soluciones de perforación superiores, consolidamos nuestra posición como el socio de perforación de precisión preferido en México.

Sostenibilidad Ambiental

La sostenibilidad ambiental es una preocupación creciente en el sector industrial, y en AutoDrill tomamos nuestra responsabilidad en serio. Reconocemos que las operaciones de perforación industrial pueden tener impactos ambientales significativos, desde el consumo de energía hasta la producción de residuos. En consecuencia, estamos comprometidos a adoptar prácticas sostenibles siempre que sea posible, como la optimización del uso de energía, el reciclaje de materiales y la minimización de residuos.

La implementación de estas prácticas no solo ayuda a reducir nuestra huella ecológica, sino que también se alinea con los valores de nuestros clientes, muchos de los cuales priorizan la sostenibilidad en sus operaciones. Creemos que al dar ejemplo, podemos inspirar un cambio positivo dentro de la industria.

Soluciones de Perforación Personalizadas

Cada proyecto que emprendemos en AutoDrill es único, con su propio conjunto de desafíos y requisitos. Reconociendo esto, no ofrecemos soluciones genéricas; nos especializamos en crear soluciones de perforación personalizadas adaptadas a las necesidades específicas de cada cliente. Ya sea desarrollando una broca a medida para un material en particular o diseñando un sistema de perforación completo desde cero, nuestro equipo tiene la experiencia y la creatividad para enfrentar cualquier desafío.

Este enfoque ha dado lugar a muchas colaboraciones exitosas y proyectos innovadores. Al escuchar a nuestros clientes y comprender sus necesidades únicas, podemos ofrecer soluciones que realmente marcan la diferencia.

Manteniéndonos a la Vanguardia

En el mundo acelerado de la manufactura industrial, mantenerse a la vanguardia es esencial. En AutoDrill, exploramos continuamente nuevas tecnologías, técnicas y materiales que pueden mejorar nuestras capacidades de perforación. Desde asistir a conferencias de la industria hasta invertir en investigación y desarrollo, estamos comprometidos a mantenernos en la vanguardia del sector de la perforación.

Nuestra dedicación a la innovación no solo nos mantiene competitivos, sino que también garantiza que nuestros clientes se beneficien de las soluciones de perforación más avanzadas disponibles. Es este enfoque visionario el que ha establecido a AutoDrill como líder en servicios de perforación de precisión en México.

Entendiendo la Importancia del Taladro Industrial

En AutoDrill, vemos al taladro industrial no solo como una herramienta, sino como un elemento fundamental de la manufactura moderna. La precisión y eficiencia que aporta a los proyectos, independientemente del material, pueden impactar significativamente en el resultado. Es como tener un caballo de batalla confiable; sabes que puedes contar con él para entregar, especialmente al trabajar en componentes críticos en industrias como la automotriz o aeroespacial. Imagina tratar de alcanzar los estándares exigentes sin la precisión de un taladro industrial; es casi imposible. Por eso, en AutoDrill, invertimos en taladros industriales de alta calidad y entrenamos constantemente a nuestro equipo para dominarlos.

Elección del Taladro Industrial Correcto

Cuando se trata de seleccionar un taladro industrial, el equilibrio es clave. Demasiada potencia sin precisión puede llevar a resultados desastrosos, mientras que muy poca potencia puede no lograr el trabajo, especialmente con materiales difíciles. Es un poco como encontrar la receta perfecta donde todo encaja perfectamente. A lo largo de los años, hemos perfeccionado nuestra capacidad para igualar el taladro al proyecto, asegurando que nunca comprometamos la calidad o la eficiencia. Para cualquiera que esté considerando comprar un taladro industrial, recomendaría enfocarse también en la versatilidad. La capacidad de adaptarse a diferentes materiales y requisitos sin perder precisión es invaluable.

Innovaciones en la Perforación Industrial

El mundo del taladro industrial siempre está avanzando, y mantenerse al tanto significa estar al tanto de estas innovaciones. Para nosotros en AutoDrill, incorporar los últimos avances tecnológicos en nuestros servicios ha sido un cambio de juego. Por ejemplo, la evolución de los materiales de las brocas nos ha permitido perforar con más precisión y menos desgaste. De manera similar, la tecnología CNC ha revolucionado nuestro enfoque al permitirnos ejecutar tareas de perforación complejas con una precisión asombrosa. Es similar a la diferencia entre dibujar manualmente un diseño complejo y usar un programa de software sofisticado que asegura que cada línea sea perfecta.

Compromiso con la Calidad y la Sostenibilidad

Nuestra dedicación va más allá de seleccionar el mejor taladro industrial; impregna toda nuestra operación. No se trata solo de lograr precisión en la perforación; se trata de mantener la calidad en cada aspecto. Esto incluye optar por prácticas ambientalmente sostenibles. Puede sorprender a algunos, pero la sostenibilidad y la perforación industrial pueden ir de la mano. Por ejemplo, optimizar el uso de energía o reciclar materiales puede reducir significativamente nuestra huella ecológica. Esto no es solo bueno para el planeta; resuena con nuestros clientes que valoran la sostenibilidad tanto como nosotros. Se trata de hacer nuestra parte para liderar con el ejemplo en la industria.

Creación de Soluciones de Perforación Personalizadas

Cada proyecto es único y viene con su propio conjunto de desafíos. Por eso, las soluciones genéricas no siempre son suficientes. En AutoDrill, hemos construido nuestra reputación en poder enfrentar estos desafíos únicos, creando soluciones personalizadas que satisfacen las necesidades exactas de nuestros clientes. Ya sea una broca personalizada para un material particularmente resistente o el diseño de un sistema completo de perforación, nuestro equipo prospera en la creatividad e innovación. Es como resolver un puzzle complejo; cada pieza debe encajar perfectamente para lograr el resultado deseado.

Manteniéndonos Competitivos con la Innovación

En el mundo acelerado de la manufactura industrial, la innovación no es solo una palabra de moda, es una necesidad. En AutoDrill, nuestro compromiso de explorar nuevas tecnologías, técnicas y materiales es lo que nos distingue. Esta dedicación no se trata de estar al tanto de las tendencias; se trata de redefinirlas. Al empujar continuamente los límites, no solo mantenemos nuestra competitividad, sino que también garantizamos que nuestros clientes reciban las soluciones de perforación más avanzadas disponibles. Es un compromiso que no solo ha definido nuestro pasado, sino que también dictará nuestro éxito futuro.

San Luis Potosi SLP 78395